Condition monitoring

Condition monitoring

The vibration-based condition monitoring of rotating devices is still the most efficient and reliable way to determine the mechanical condition of the device and the corrective actions needed.

Based on the information gained from the vibration measurements, the faulty components and repair schedule can be determined early.

Condition monitoring ensures:

- Better reliability

- Reduction of unplanned shutdowns

- Improvement of the planning and implementation of the maintenance work (spare parts, resources, schedules)

Information produced by the vibration studies

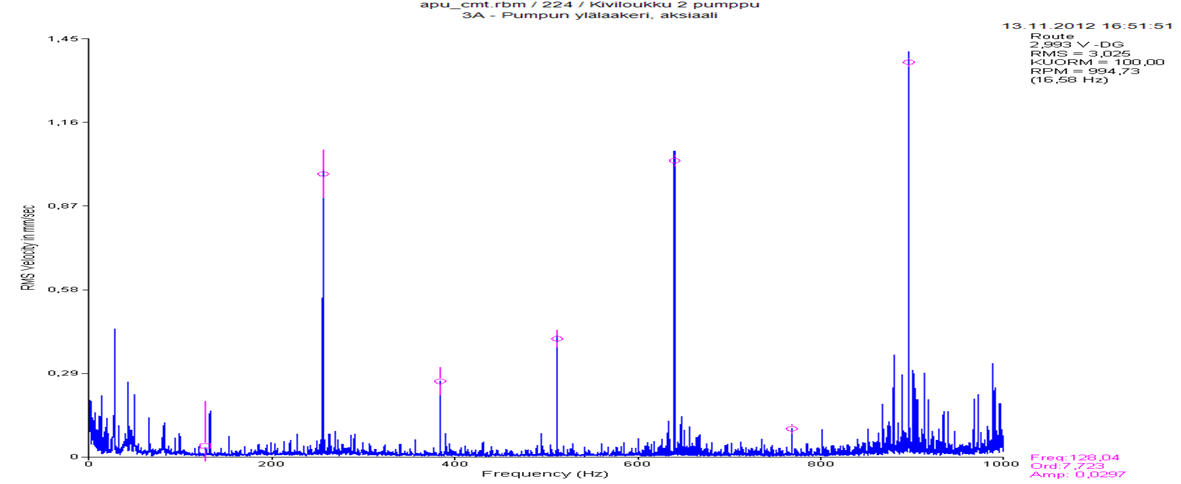

Measured vibration responses of rotating mechanical devices include its mechanical condition and changes in it.

This is based on the fact, that each failure mode creates unique vibration frequency component, which can be identified from the vibration measurement results, failure modes such as:

- Imbalance

- Bearing faults

- Gearwheel faults

- Misalignments

Condition monitoring services

Our services on considering the condition monitoring are:

- Start-up of the factory’s condition monitoring

- Implementation of the condition monitoring

- Remote condition monitoring services

- Training

We use the following condition monitoring analyzers with the related software:

- CSI 2130 machinery health analyzer

- SKF Microlog Analyzer AX

- Fag Detector III

| BEARING TYPE | #B/R | FTF | BSF | BPFO | BPFI | |

|---|---|---|---|---|---|---|

| KOY NU2230 | 18 | .433 | 3.683 | 7.800 | 10.200 | 16.6 Hz x 7.800 = 129.5 Hz |

| SKF NU2230 | 17 | .433 | 3.683 | 7.367 | 9.633 |